Our sawing program completes finishing in laser melting with outstanding quality and unrivalled economic efficiency.

And is thus considerably faster than the conventional wire eroding machines. Rapid makeready times and significantly lower procurement costs give you a competitive edge and make the cash register smile.

Process steps in the additive manufacturing

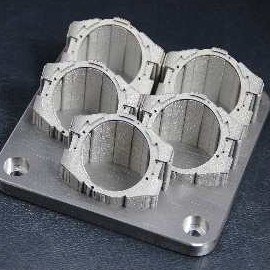

Most Additive manufacturing processes especially metal laser melting require strategies for further work after the printing processes. Starting from separating build plate and part in a safe, quick an economic way until the finishing process of each part.

3D CAD model

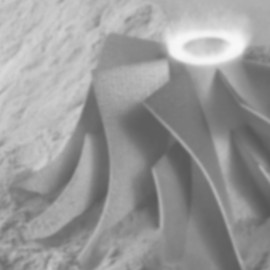

Additive manufacturing

Cleaning and heat treatment

Separation process of base plate

Cleaning and finishing

Klaeger offers you many advantages

- Developed sawing machine just for the requirements of 3D printing parts

- Cutting solution to separate the parts from their baseplates.

- Suction system for a safety and healthy working, according to the ATEX guideline (Zone22)

- Incl. spark traps, 3 compartment filtration and water separator

- Easy to clean

- Suitable for all baseplates and AM materials

- from 90x90x90 mm

- up to 800x400x500 mm

- Experience with all materials:

- inconel 718/625

- titanium

- aluminium

- stainless steel (SS420, 1.4404)

- cobald chrome (CoCr1)

- gold

- silver

- special alloys

- remanium alloys

for the following areas:

- Aerospace

- Automotive

- Dental

- Medicine

- Tools

- Jewellery

Post-processing Cutting technologies comparison

| Klaeger saw | Wire eroding machine | |

|---|---|---|

| Acquisition cost | Medium | High |

| Maintenance costs | Low | Medium |

| Operating steps | Easy to operate | Trained personal needed |

| Cutting time | 5-20 min | 240-400 min |

| Cutting channel | Approx. 2 mm | Approx 0,5 –1 mm |

| Cost per Cut | Approx. 20-60 € | Approx. 350 –900 € |