An excellent sawing machine is definitely the basis for quality cutting, but on its own it is not sufficient: poor blades can jeopardize the result, while inadequate accessories can diminish the efficiency of your plant.

Treat your sawing machine to the best blades and accessories on the market, choosing from our wide selection.

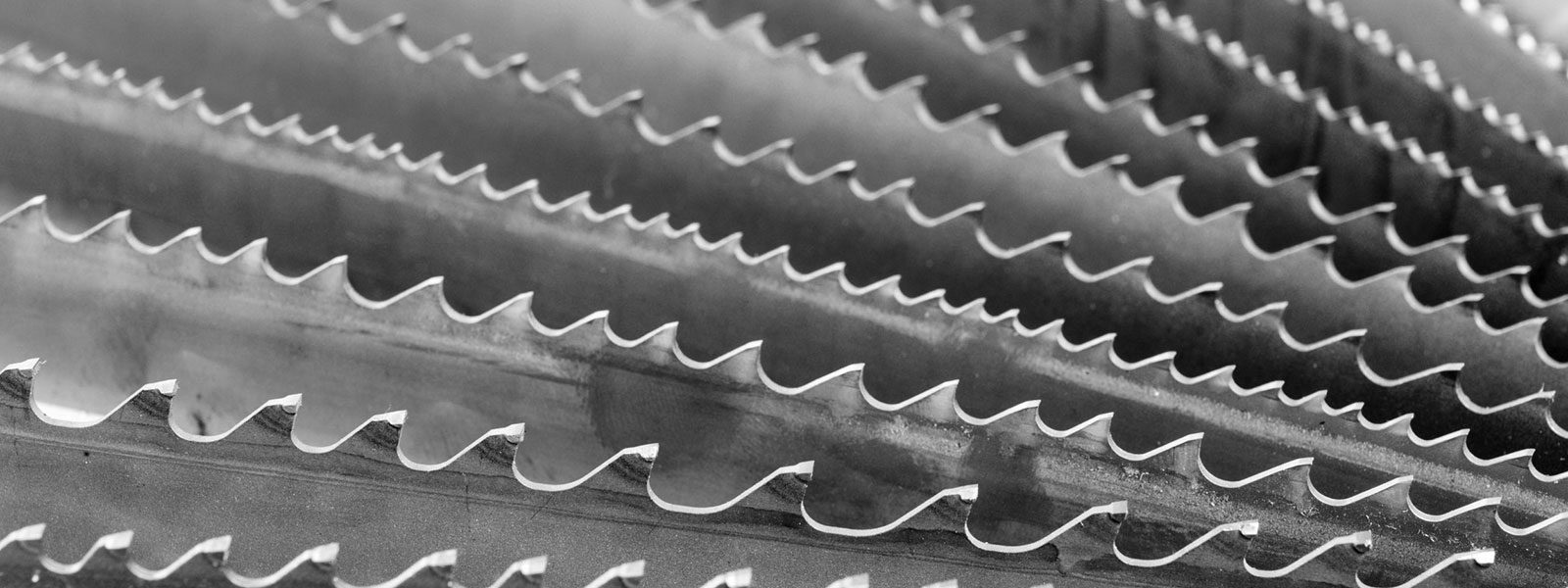

Blades

Top quality blades not only enhance the performance of your saws, providing more reliable and repeatable machining: they also last longer, proving more convenient than cheaper replacements.

The obvious choice for Klaeger machines, our blades can improve the productivity of other saws too.

Choose the ideal solution- bimetal or tungsten carbide – from our wide range.

Bimetal blades

OMNIUM

The all-purpose M42 for large profiles and solid bars

- universal use for single and serial cuts

- large profiles and solid materials

- Layer and bundle cut

- Steels up to 40 HRC

- non-ferrous metals

|

Dimensions |

||||||||

|

Width x thickness |

Tooth pitch in ZpZ |

|||||||

|

mm |

Inch |

5/8 |

4/6 |

3/4 |

2/3 |

1.4-2 |

1-1.4 |

0.75-1.25 |

|

27 x 0.90 |

1-1/16 x 0.035 |

|||||||

|

34 x 1.10 |

1-3/8 x 0.042 |

|||||||

|

41 x 1.10 |

1-5/8 x 0.042 |

|||||||

|

41 x 1.30 |

1-5/8 x 0.050 |

|||||||

|

54 x 1.30 |

2-1/8 x 0.050 |

|||||||

|

54 x 1.60 |

2-1/8 x 0.063 |

|||||||

|

67 x 1.60 |

2-5/8 x 0.063 |

|||||||

|

80 x 1.60 |

3-1/8 x 0.063 |

|||||||

|

Contact length |

[mm] |

30-60 |

50-90 |

80-150 |

130-250 |

250-500 |

500-800 |

550-1200 |

|

[Inch] |

1.2-2.4 |

2-3.5 |

3.2-5.9 |

5.1-9.8 |

9.8-19.7 |

19.7-31.5 |

21.7-47.2 |

|

VERTIGO

A M42 all-purpose band saw blade for small cross-sections and profiles

- all metals up to 1000 N/mm²

- Smooth running thanks to variable tooth pitch and 0° rake angle

|

Dimensions |

|||||||

|

Width x thickness |

Tooth pitch in ZpZ |

||||||

|

mm |

Inch |

10/14 |

8/12 |

6/10 |

5/8 |

4/6 |

3/4 |

|

6 x 0.65 |

1/4 x 0.025 |

||||||

|

6 x 0.90 |

1/4 x 0.035 |

||||||

|

10 x 0.90 |

3/8 x 0.035 |

||||||

|

13 x 0.65 |

1/2 x 0.025 |

||||||

|

13 x 0.90 |

1/2 x 0.035 |

||||||

|

20 x 0.90 |

3/4 x 0.035 |

||||||

|

27 x 0.90 |

1-1/16 x 0.035 |

||||||

|

34 x 1.10 |

1-3/8 x 0.042 |

||||||

|

41 x 1.30 |

1-5/8 x 0.050 |

||||||

|

54 x 1.30 |

2-1/8 x 0.050 |

||||||

|

Contact length |

[mm] |

< 20 |

10-30 |

20-50 |

30-60 |

50-90 |

80-150 |

|

[Inch] |

< 0.8 |

0.4-1.2 |

0.8-2 |

1.2-2.4 |

2-3.5 |

3.2-5.9 |

|

RUBIN

The good-price per value band saw for thin-walled profiles and for many sawing tasks

- simple workshop operation

- small and medium workpiece dimensions

- profiles and solid materials

|

Dimensions |

||||||||||

|

Width x thickness |

Tooth pitch in ZpZ |

|||||||||

|

mm |

Inch |

10/14 |

8/12 |

6/10 |

5/8 |

4/6 |

3/4 |

2/3 |

1.4-2 |

1-1.4 |

|

13 x 0.65 |

1/2 x 0.025 |

|||||||||

|

20 x 0.90 |

3/4 x 0.035 |

|||||||||

|

27 x 0.90 |

1-1/6 x 0.035 |

|||||||||

|

34 x 1.10 |

1-3/8 x 0.042 |

|||||||||

|

41 x 1.30 |

1-5/8 x 0.050 |

|||||||||

|

54 x 1.60 |

2-1/8 x 0.063 |

|||||||||

|

67 x 1.60 |

2-5/8 x 0.063 |

|||||||||

|

Contact length |

[mm] |

< 20 |

10-30 |

20-50 |

30-60 |

50-90 |

80-150 |

130-250 |

250-500 |

500-800 |

|

[Inch] |

< 0.8 |

0.4-1.2 |

0.8-2 |

1.2-2.4 |

2-3.5 |

3.2-5.9 |

5.1-9.8 |

9.8-19.7 |

19.7-31.5 |

|

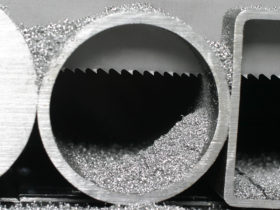

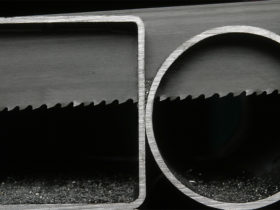

STRUCTURE

The perfect band saw blade to cut profiles

- for profiles and girders in metal and steel construction

- optimal for cutting interrupted cutting channel

- Resistant to tooth breakout thanks to extremely sturdy tooth contour

- Less susceptibility to vibrations due to the special tooth shape

- M42 tooth edge with positive rake angle

|

Dimensions |

|||||||

|

Width x thickness |

Tooth pitch in ZpZ |

||||||

|

mm |

Inch |

12/16 |

8/11 |

5/7 |

4/6 |

3/4 |

2/3 |

|

20 x 0.90 |

3/4 x 0.035 |

||||||

|

27 x 0.90 |

1-1/16 x 0.035 |

||||||

|

34 x 1.10 |

1-3/8 x 0.042 |

||||||

|

41 x 1.30 |

1-5/8 x 0.050 |

||||||

|

54 x 1.30 |

2-1/8 x 0.050 |

||||||

|

54 x 1.60 |

2-1/8 x 0.063 |

||||||

|

67 x 1.60 |

2-5/8 x 0.063 |

||||||

|

Contact length |

[mm] |

< 20 |

10-50 |

40-70 |

50-90 |

90-150 |

130-250 |

|

[Inch] |

< 0,8 |

0,4-2 |

1,6-2,8 |

2-3.5 |

3.5-5.9 |

5.1-9.8 |

|

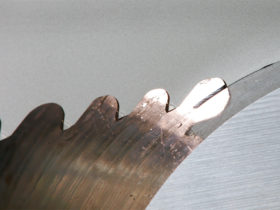

Hard metal blades

CARBOSPEED

The carbide blade to cut aluminium and non ferrous metals with the best price-value

- Aluminum and aluminum alloys, copper and copper alloys in solid material or profiles

- short cutting times

- Low finishing due to perfect surface quality

- Ground trapezoid tooth with positive rake angle

| Dimensions | |||||

| Width x thickness | Tooth pitch in ZpZ | ||||

| mm | Inch | 3/4 | 2/3 | 1.4-2 | 0.85-1.15 |

| 13 x 0.80 | 1/2 x 0.032 | ||||

| 20 x 0.90 | 3/4 x 0.035 | ||||

| 27 x 0.90 | 1-1/16 x 0.035 | ||||

| 34 x 1.10 | 1-3/8 x 0.042 | ||||

| 41 x 1.30 | 1-5/8 x 0.050 | ||||

| 54 x 1.30 | 2-1/8 x 0.050 | ||||

| 54 x 1.60 | 2-1/8 x 0.063 | ||||

|

Contact length |

[mm] |

90-150 |

130-250 |

250-500 |

700-1200 |

|

[Inch] |

3.5-5.9 |

5.1-9.8 |

9.8-19.7 |

27,6-47,2 | |

CARBOMAX

The all-round carbide blade

- suitable for all steels

- solid material and thick-walled tubes

- for band saws without carbide package

- Sturdy design for increased wear resistance

| Dimensions | |||||||

| Width x thickness | Tooth pitch in ZpZ | ||||||

| mm | Inch | 3/4 | 2/3 | 1.7-2 | 1.4-2 | 1-1.4 | 0.7-1 |

| 27 x 0.90 | 1-1/16 x 0.035 | ||||||

| 34 x 1.10 | 1-3/8 x 0.042 | ||||||

| 41 x 1.30 | 1-5/8 x 0.050 | ||||||

| 54 x 1.30 | 2-1/8 x 0.050 | ||||||

| 54 x 1.60 | 2-1/8 x 0.063 | ||||||

| 67 x 1.60 | 2-5/8 x 0.063 | ||||||

| 80 x 1.60 | 3-1/8 x 0.063 | ||||||

| Contact length |

[mm] |

90-150 | 130-250 | 200-300 | 250-500 | 500-800 | 800-2000 |

|

[Inch] |

3.5-5.9 | 5.1-9.8 | 7.9-11.8 | 9.8-19.7 | 19.7-31.5 | 31.5-78.7 | |

3D blades

3D CUT

The blade studied to give best results with 3d Cut machines

- All steels and non-ferrous metals

- Low finishing thanks to good surface quality

- Usable also for machines without carbide-package

|

Dimensions |

|||||||

|

Width x thickness |

Tooth pitch in ZpZ |

||||||

|

mm |

Inch |

3/4 |

2/3 |

1.7-2 |

1.4-2 |

1-1.4 |

0.7-1 |

|

27 x 0.90 |

1-1/16 x 0.035 |

||||||

|

34 x 1.10 |

1-3/8 x 0.042 |

||||||

|

41 x 1.30 |

1-5/8 x 0.050 |

||||||

|

54 x 1.30 |

2-1/8 x 0.050 |

||||||

|

54 x 1.60 |

2-1/8 x 0.063 |

||||||

|

67 x 1.60 |

2-5/8 x 0.063 |

||||||

|

80 x 1.60 |

3-1/8 x 0.063 |

||||||

|

Contact length |

[mm] |

90-150 |

130-250 |

200-300 |

250-500 |

500-800 |

800-2000 |

|

[Inch] |

3.5-5.9 |

5.1-9.8 |

7.9-11.8 |

9.8-19.7 |

19.7-31.5 |

31.5-78.7 |

|

Complements

With a top-notch machine and high quality blades, would you risk a drop in performance by using cheap lubricants?

Our cutting oils are the appropriate complement to your cutting system – and with our microlubricator system, there is no wastage or complex maintenance involved.

And for an automated feeding or discharge of cut elements, our conveyors are just what you need.

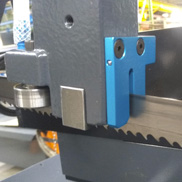

CoolTool minimum quantity lubrication

CoolTool is the ideal cooling and lubricating solution for sawing, milling, drilling and thread cutting:

CoolTool is the ideal cooling and lubricating solution for sawing, milling, drilling and thread cutting:

- self-assembling in no time at all

- harmless plant seed lubricant: easy to clean, no disposal costs

- longer working life for your blades and sawing machines

CoolTool is easy to fit on all saws (including circular saws and those already in use).

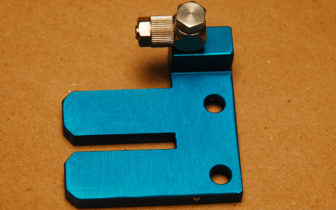

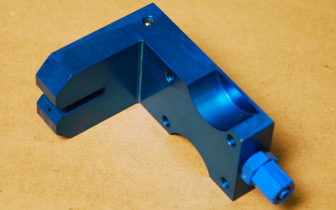

4 Nozzle variants

- 3-way spray nozzle for circular saws with feed through the sawblade cover

- 3-way spray nozzle for circular saws mounted either above or below the sawbalde cover

- Double spray nozzle for band sawing machines

- Universal spray nozzle with stable magnetic holder for drilling, turning, milling and thread cutting.

- Sawblade cover also available.

CoolTool Fluid 5 litres

- Only plant-based, especially modified rapeseed oil, no fog, harmless for health.

- Economical: enough for approximately 100 – 150 operation hours.

- Specially designed supply canister ensures maximum efficiency.

Coolant concentrate 10 litres

Special coolant concentrate

- free from mineral oil

- optimized for sawing machines

This excellent coolant concentrate reduces the operation costs of saw blades.